After years of lagging behind competitors in Asia, semiconductor manufacturers in the United States say they are poised for a jumpstart – thanks to a series of government investments, one of which was announced Monday in Vermont.

The growing adoption of electric vehicles, upgrades to our power grids, and faster data on 5G and eventually 6G smartphones are some of the developments that will require a next generation of semiconductor that will be developed and produced by GlobalFoundries at its facility in Essex Junction, the company said.

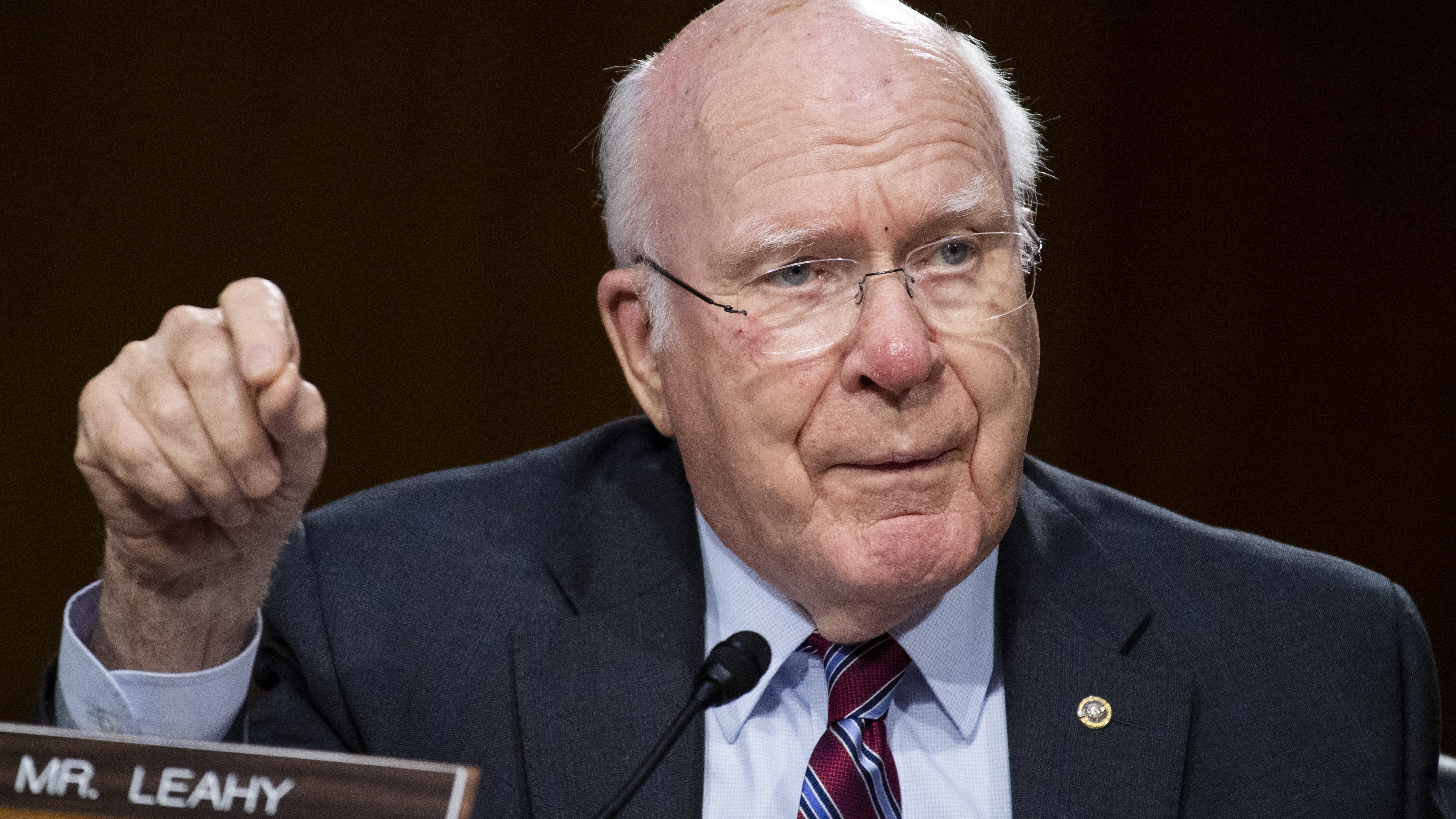

"We’re going to be building it – why not here in Vermont?" Sen. Patrick Leahy, a Democrat, asked rhetorically after announcing $30 million in federal funding to spark development and manufacturing of a variety of microchips using new materials.

"It’s a reinvention," GlobalFoundries CEO Tom Caulfield observed of gallium nitride or GaN semiconductors – which he said will better handle high heat and power needs than previous generations of chips could.

Get New England news, weather forecasts and entertainment stories to your inbox. Sign up for NECN newsletters.

Caulfield explained the technology will be especially helpful as electric cars get more and more efficient.

"For fast charging of batteries – for better precision battery management," Caulfied added, providing two examples of performance improvements GaN chips will help the auto industry achieve.

Get updates on what's happening in New England to your inbox. Sign up for our News Headlines newsletter.

That federal funding for the Vermont plant is separate from the $52.7-billion pot of money Washington set aside to specifically strengthen domestic chipmaking – part of a larger package of technology investments.

The CHIPS and Science Act President Joe Biden authorized this summer, which garnered bipartisan support in Congress, aims to invest in America’s chip-making capacity and reduce reliance on foreign-made semiconductors. The White House said the U.S. currently only produces about 10% of the world's semiconductor supply, relying on East Asian suppliers for more than 75% of production.

As NECN & NBC10 Boston reported in June of 2021, the microchip shortage was felt in Vermont in a variety of ways – including at car dealerships, which struggled to secure vehicles from car manufacturers who needed chips.

The government is right now setting up a system for manufacturers looking for funds through the CHIPS Act to use to retool their facilities.

"As the process gets better defined, we’ll be putting in our applications to demonstrate the outcomes we will drive with that type of funding across our footprint in the U.S.," Caulfield said Monday in an interview with NECN & NBC10 Boston.

Ken McAvey, the vice president and general manager of the GlobalFoundries manufacturing facility in Essex Junction, said he is grateful Sen. Leahy also pursued funding for workforce development initiatives.

"We’re going to be able to grow our partnerships with both Vermont Technical College, with the University of Vermont, and then grow our outreach to local high schools and especially technical high schools," McAvey noted. "So for us, having the next generation of team members to continue the legacy of the site – we’re really excited about that."

When the CHIPS Act was up for debate, some critics did wonder why taxpayer money would flow to profitable plants. Monday, Leahy insisted a key reason is national security, pointing out the GlobalFoundries facility in Essex Junction provides the U.S. Department of Defense with specialized chips for some of its most sensitive systems.